BENEFITS

- NORMAL LUBRICATION NOT REQUIRED

- NO TIME WASTED CLEANING THE LUBE SPATTER FROM YOUR BIKE

- MORE POWER TO THE WHEEL

- MONEY SAVINGS ON LUBE, FUEL CONSUMPTION AND BIKE CLEANERS

- ENVIRONMENTALLY FRIENDLY

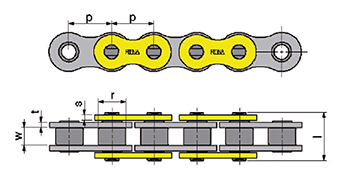

| p | w | r | t | s | l | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHAIN | PITCH | INNER WIDTH | ROLLER ⌀ | PLATE THICKNESS | PIN LENGTH | WEIGHT | AVERAGE TENSILE STRENGTH |

||||||||||

| International Reference |

Regina Reference |

mm | in. | mm | in. | mm | mm | mm | mm | kg/m | kg/100 links |

libs/100 links |

N | Lbs | Seal | Color | Connecting link type |

| 525 | 137 HPE | 15,875 | 5/8 | 7,95 | 5/16 | 10,23 | 2,4 | 2,2 | 23,0 | 1,29 | 2,05 | 4,52 | 41.000 | 9,217 | ZR | G | 19 |

| 520 | 135 HPE | 15,875 | 5/8 | 6,35 | 1/4 | 10,23 | 2,2 | 2,2 | 21,0 | 1,19 | 1,90 | 4,20 | 36.000 | 8,093 | ZR | G | 19 |

G = Gold

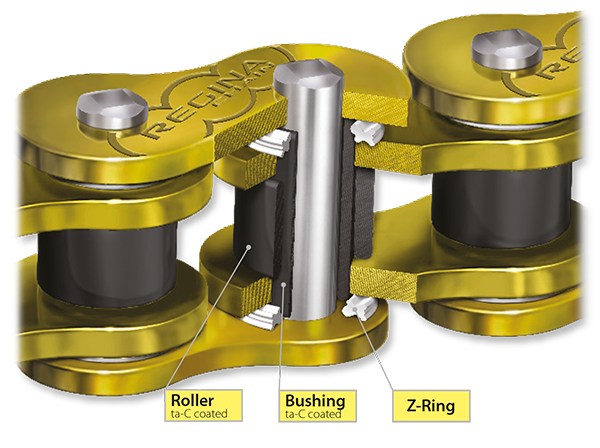

The Tetrahedral Amorphous Carbon (ta-C) coating, currently considered as the most advanced among DLC (Diamond Like Carbon) coatings, applied on the surfaces of the bushings and the rollers of the HPE Chain, combining high hardness with a low coefficient of friction

- eliminates the need of periodic re-lubrication, while ensuring at least the same mileage obtained with a normal chain regularly lubricated every 500 km

- reduces energy dissipation and increases efficiency in the chain drive

- eliminates lubricant spatter during operation, minimizing environmental impact.

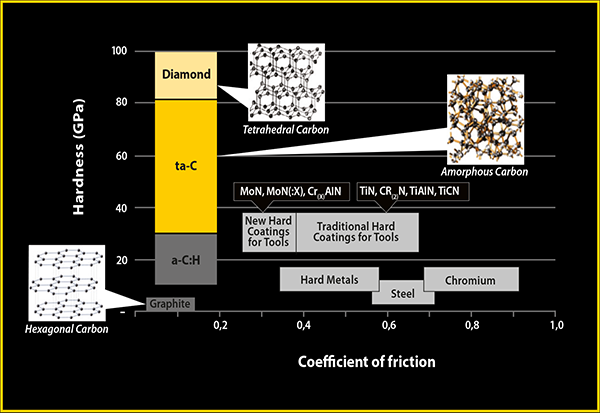

ta-C: THE CARBON COATING CLOSEST TO DIAMOND

Pure Carbon is present in nature only in two crystalline physical states: Diamond (atoms in Tetrahedral bonding arrangement) and graphite (atoms in Hexagonal Planar bonding arrangement).

ta-C is a synthetic state of pure Amorphous Carbon in which up to 80% of the atoms are bonded to each other with a Tetrahedral arrangement, in the same way of pure Diamond. For this reason, among all so called “DLC” (Diamond Like Carbon) coatings, the physical properties of ta-C (such as hardness & coefficient of friction) are the closest to pure Diamond, which is the hardest material on Earth.

HPE CHAIN INSTALLATION

- a chain drive using an HPE Chain does not require ta-C coated front and rear sprockets

- when installing a new HPE Chain, it is strongly recommended to replace front and rear sprockets with new ones. Sprockets must be made of steel

www.reginachain.net – Chain Maintenance section, for detailed instructions.

HPE CHAIN MAINTENANCE, CLEANING AND TENSIONING

To guarantee its best functionality and aesthetics over time, follow 3 simple rules:

- clean and re-lubricate the chain

- after washing your bike

- after using your bike in wet conditions and / or in salty or dusty environments

- before storing your bike at the end of the riding season (winter season)

- re-lubricate the chain once a year

- check correct chain tensioning every 3.000 Km.

www.reginachain.net – Chain Maintenance section, for detailed instructions.